3 In 1 Combined H Beam Production machine

$38800-43115 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,your request |

$38800-43115 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,your request |

Model No.: PHJ0815

Status: New

Applicable Industry: Manufacturing Plant, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Long Service Life, Low Maintenance Cost, Multifunctional, High Productivity, Easy To Operate

Name: Steel Structure Assembling Welding H Beam Making Machine

Web Height: 200-1500 mm

Web Thickness: 6-16 mm

Flange Width: 200-800 mm

Flange Thickness: 6-20mm

Assembly And Welding Speed: 0.35-3 m/min

Roller Conveyor Motor Power: 6KW

Flux Recycling Machine Motor Power: 3KW*2=6KW

Pump Station Power: 4KW

Welding Source Power: 69 KW*2=138 KW

| Selling Units | : | Set/Sets |

| Package Type | : | In wooden case, steel frame, export packing |

| Download | : |

|

Parameter

H-beam vertical assembling, welding and straightening multi-function integrated machine is a high-efficiency equipment for the production of welded H-beams. It can simultaneously complete H-beam assembly, submerged arc welding, and flange plate welding deformation on the same machine.The machine occupies a small area which can save installation space. It saves the hoisting and turning time between each process with single machine,then the efficiency is greatly improved, and the cost is reduced. It is a high-tech, economical and practical H-beam production equipment.

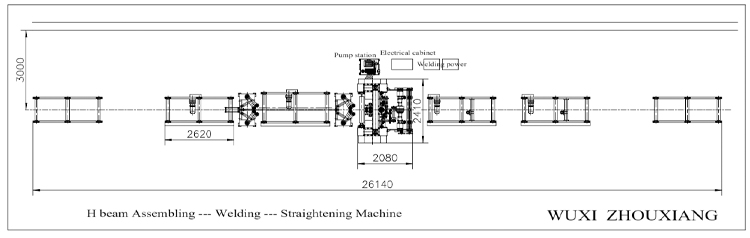

H beam Assembling, welding, straightening machine

Metric units:

| Web plate height | 200~1500 mm |

| Web plate thickness | 6~14 mm |

| Flange plate width | 200~800 mm |

| Flange plate thickness | 6~20 mm |

| H beam length | 6000~15000 mm or as user’s request |

| Assembly and welding speed | 0.35~3 m/min |

| Main machine power | 4 KW |

| Roller conveyor motor power | 4 x 0.55 Kw=2.2 kW |

| Flux recycling machine motor power | 2 x 3 kw=6 kW |

| Pump station power | 4 kW |

| Welding source power | 2 x 69 kW=138 kW (Lincoln DC-1000) |

| Above are our standard model, it can be designed and manufactured according to customer’s request. | |

H beam Assembling Welding and Straightening Machine Details:

1) Two sets welding gun weld the welding seam of H-beam at the same time.

2) Lincoln welding power and control system are widely used in the H beam assembling welding and straightening machine

2) Lincoln welding power and control system are widely used in the H beam assembling welding and straightening machine

3) H-beam assembly, submerged arc welding and flange plate straightening system

What are the characteristics of steel structure?

1. High strength and light weight

The strength of steel structure is very high, and its strength is higher than that of concrete and wood. And light weight, easy to transport and install.

2. Good plasticity and uniform material

The steel structure has good anti-seismic effect, uniform material and high reliability.

3. High degree of mechanization

The steel structure is easy to assemble, has high production efficiency and short construction period, and is a structural grid frame with a high degree of industrialization.

4. Good sealing

Its welded structure has good sealing performance, so the constructed building is strong and has good thermal insulation effect.

Advantages and disadvantages of H-beam assembling welding straightening machine:

Disadvantages: During 45° fillet welding, molten iron tends to flow to one side of the bottom; when assembling, due to the deformation of the steel plate, uneven kerfs, etc., the assembly process is advanced or the hydraulic pressure is unbalanced. The pressure roller must be released in time to make the web decompression or progress is smoother, so during the assembly process, the error value should be continuously measured.

Advantages: The three functions of assembly, welding and correction are combined together, which greatly saves manpower and workshop space; the left and right sides are welded at the same time, and the production efficiency is greatly improved; only one worker can complete the operation, which is convenient to use; single arc single wire or single-arc double-wire welding method is optional, and the welding seam is relatively firm.

Which industries are the 3-in-1 machine suitable for?

The H beam assembling welding and straightening machine is suitable for construction machinery, ships, buildings, bridges, industrial plants, etc. Compared with the traditional steel structure production line, it is more convenient and efficient, and it is a wise choice for the production of light steel in modern industry. There are many reasons and benefits of steel structure design applied in different fields. The steel structure is a robust design that can be effectively preserved for decades and can be modified and recycled as needed. New York's Brooklyn Bridge and Empire State Building are prime examples.

Wuxi Zhouxiang complete set of welding equipment plant is a famous China manufacturer of H beam Welding equipment. Our factory is located in Wuxi city, China---was established in 1991. The company has fixed assets of more than 20 million US dollars, a factory area of 100,000 square meters, and annual sales of more than 40 million US dollars.We have full control of production from steel plate delivery, through to site installation and commissioning,design and manufacture highly sophisticated heavy engineering machinery, our research and development weld centre also more than 100 engineering. Zhouxiang Complete Set of Welding Equipment Co., Ltd is a national high-tech enterprise, with China's national CCC certification, CE, TüV, GS certification, ISO9001 international quality system certification, etc. Main products of Zhouxiang plant: 1)H beam productions line: CNC control Flame/ plasma cutting machine .H beam assembly machine.H Beam Welding Machine.H beam flange plate straightening machine. H beam shot blasting machine.H beam End Face Milling Machine.H beam assembly-welding-straightening machine.Horizontal H beam productions line etc. 2)BOX column production line: Steel plate groove milling machine.Box column assembly machine.Box column welding machine.Box column electroslag welding.Box beam shot blasting machine.Box beam end Face Milling Machine etc. 3)Welding Rotator: Portable pipe rotator.Conventional rotator.Self-aligned welding rotator.Wind tower productions line etc.Anti-creeping welding rotato etc. 4)Welding Manipulator: Column and Boom .Platform welding manipulator 5)Welding Positioner: Tilting positioner.L type welding positioner.Head and tail stock welding positioner etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.